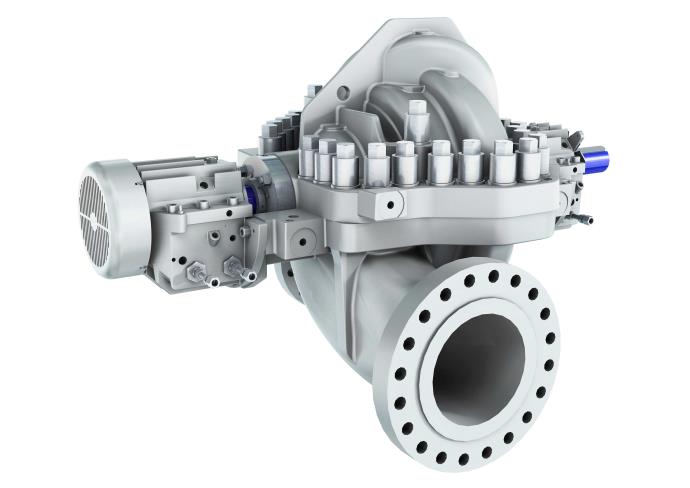

The MSD-RO is the result of Sulzer’s experience in supplying high pressure pumps for large SWRO plants worldwide, with a total of 2.5 million m3/d installed capacity. It is a two stage, split casing, single suction pump, mainly for high pressure membrane feed in SWRO desalination applications.

The newest Axially Split High Pressure SWRO pump

The MSD-RO is based on our famous MSD range of axially split, multistage, double volute centrifugal pumps, typically used in the Oil and Gas industry as well as in desalination high pressure applications.

The MSD-RO meets the needs of a high pressure pump for the desalination market for large Seawater Reverse Osmosis (SWRO) pumps, covering SWRO train capacities from 20,000 to 30,000 m3/d.

Key characteristics

| Capacities | Up to 1,600 m3/h / 7,000 US gpm |

| Heads | Up to 650 m / 2,150 ft |

| Pressures | Up to 90 bar / 1,305 psi |

| Temperatures | Up to 60°C / 140°F |

| Maximum speed of rotation | Up to 3,600 rpm |

MSD-RO Design

It is a two stage in back-to-back arrangement, axially split casing, single suction pump which has been developed mainly for high pressure membrane feed in Reverse Osmosis (RO) desalination applications.

The MSD-RO pump is a sturdy and compact pump, delivering high level of hydraulic performance over its defined operating range, including exceptionally high efficiencies and optimum suction performance.

Innovation has been at the center of the MSD-RO development. As a result, the MSD-RO pump benefits from:

- A significantly more compact arrangement of the pump hydraulics

- Top class efficiency according to market needs

The meticulous design approach combined with Sulzer’s experience have resulted in a pump that performs to the highest efficiency level, whilst providing our customers with a robust, reliable, easy-to-maintain and cost-effective pump.

Main technical features as follows:

- Hydraulic configuration with two single suction impellers offers a compact design, with extremely low NPSH values and top of its class efficiency

- Special opposed, dynamically balanced impeller design for ideal axial thrust balance, increasing the overall pump efficiency by avoiding the use of balancing line

- Single, balanced, cartridge mechanical seal. Option for API 682 mechanical seal is available

- Sleeve journal and duplex angular contact thrust bearing as standard. Sleeve journal and pivot shoe thrust bearing with force oil lubrication system is available

- Robust split flanges based on heavy duty API standards

- Reduced wear parts clearances by using PEEK or honeycomb, to increase pump efficiency.

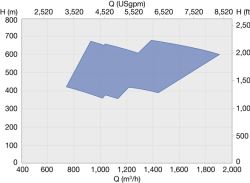

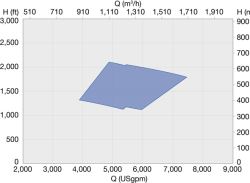

Performance range

Performance 50Hz Performance 60 Hz